Staying on top of a hill means you have beautiful sunsets and views of rolling hills that never end…

It also means a loop-run from home ends in tears or swearing, and your yard is gardening hell. We have a three-tier backyard. Getting from the first tier to the second involves planning, hiking shoes and is not recommended for people over 65.

Tier two is the perfect size for a nice thatch lapa and a pool, so we decided to improve accessibility by building flight of stairs.

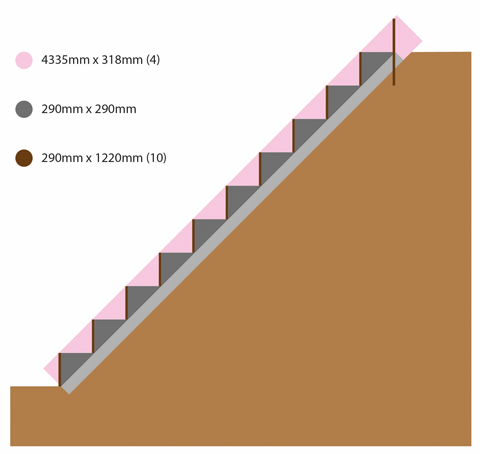

We weren’t too sure about the structural integrity of the embankment, so we decided to use concrete to build our stairs. With some advice from my handy dad, we decided our stairs should be a comfortable 29mm(h) x 29mm(w) at 45º with a landing or two every five steps. This would give us enough freedom to not cast the whole thing in one batch, but rather do it in sections using the same frame.

We would build a reusable wood frame that we would assemble, cast concrete, disassemble and repeat till the stairs reached the top.

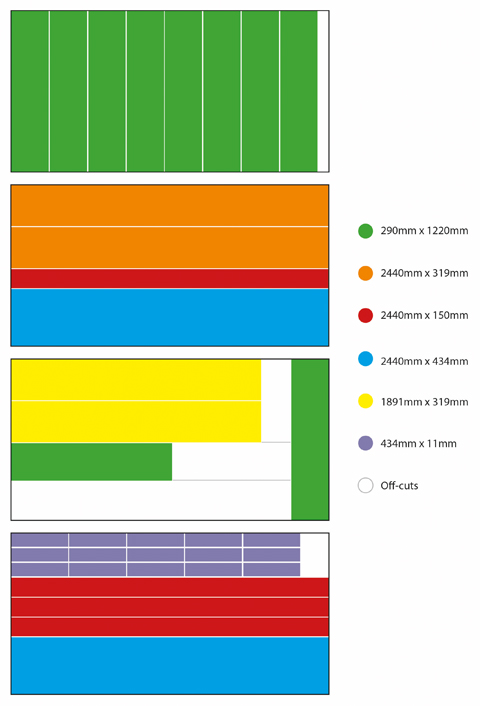

I drew up some plans. We wanted to work out what the least amount of treated super-plywood sheets were that we had to buy.

We headed to Timbercity and we asked them politely to give us four treated super-plywood sheets, pre-cut into the sizes above, and delivered to our home.

We headed to Timbercity and we asked them politely to give us four treated super-plywood sheets, pre-cut into the sizes above, and delivered to our home.

This took quite some time as they had a Christmas/New years backlog.

The wood arrived on Friday while we were attending a wedding. Saturday morning we got started.

We finished the frames and we decided to move them to the garden the following morning as it started to rain.

We finished the frames and we decided to move them to the garden the following morning as it started to rain.

Moving these frames from the 1st floor to our garden was going to be a task as they were bulky and heavy. While we were deciding if we were going to disassemble the frames or not, we discovered that the rain had damaged one of our panels.

This was in fact not treated wood like we politely requested. If we should pour concrete onto these frames, the water would damage them. Our stairs would need a lot of finishing as it would be wrinkled and we would have to throw away the wood after using it only once. We were stressed. A week earlier we had organised two guys to come and help with the concrete on Monday. It was now Sunday.

I eagerly volunteered to go back to Timbercity as I wanted to give them a piece of my mind. My husband said he would start disassembling the frames and carry all the wood downstairs to the garden.

Timbercity was obviously closed because it was Sunday.

I went to the hardware store, and they suggested I use varnish. It would’ve costed an arm and a leg, so I decided to phone handy dad again. He suggested Creosote. The hardware store guy told me it would take 3 days to dry.

I decided that Builders Warehouse was my last hope. A guy there suggested that carbolineum was the answer to all my problems.

Carbolineum is a blend of creasote and coal-tar. It smells like the stuff they used to make our roads from and is sticky as hell.

Carbolineum is a blend of creasote and coal-tar. It smells like the stuff they used to make our roads from and is sticky as hell.

The husband assembled all the parts and we started painting. We even got a friend to help us out.

The husband assembled all the parts and we started painting. We even got a friend to help us out.

It felt like 45ºC, but the man at Builders assured me that the hot, sunny weather would help our cause.

It felt like 45ºC, but the man at Builders assured me that the hot, sunny weather would help our cause.

The beer, I assured everyone, would help for the sunstroke.

So Monday the concrete started flowing:

So Monday the concrete started flowing:

Nice post 🙂

_______________________________________________________________________

Hi 🙂

Please check out my blog http://unsmileys.wordpress.com/ & http://unsmileys.co.vu/ if you want 🙂 Thank you so much.It means a lot. And you have a really nice blog 🙂 Best wishes

Happy blogging 🙂